Apollo Power has officially launched its new flexible solar panel factory in the Mevoe-Carmel park at Yoqne’am. The new factory can produce 190 mw (16 million square feet of film) annually. The company estimates this is the largest solar film factory in the world and the first of its kind in Israel. It is composed of two buildings with a total area of 2.5 acres. With a cost of more than $100 million NIS, it took more than a year and a half to construct the factory.

The present factory can produce 10 mw films, mainly for pilot projects and short series. The new factory provides the company with a 20-fold increase in production capacity and marks a significant boost to the company’s commercialization. Among other reasons, increasing production capabilities was done to realize the agreement with Tadiran Solar, which obliges the company to deliver a minimal amount of 26 mw films. Tadiran Solar will be Apollo’s exclusive distributor in the light roof market in Israel.

Any available surface could turn into a power generator

The new factory’s products will also be supplied to one of the most prestigious clients in the automotive world. In May 2022, Apollo reported the signing of its first commercial contract in the automotive industry. Today, it reveals its identity: Volkswagen, the giant German automobile manufacturer, which ordered dozens of thousands of solar films with a total value of €33 million. Those films are designed to be integrated with Volkswagen’s models in the After Market phase and are planned for delivery in mid-2024.

Apollo’s CEO, Oded Rosenberg [pictured above], told Techtime that the company’s vision is “to turn any surface under the sun into a power generator. Conventional panels are large, heavy, and breakable and, thus, cannot be installed anywhere. Our main target markets are solar films for roofs, Floating Solar, and the automotive industry – where we have the most significant competitive advantage”. Apollo was founded in 2014 and joined the Tel-Aviv stock exchange in 2017. Thanks to the films’ elasticity and their lightweight, they are easily deployed on bumpy surfaces, thus utilizing areas and buildings incapable of using conventional panels.

Quiet, low-priced energy

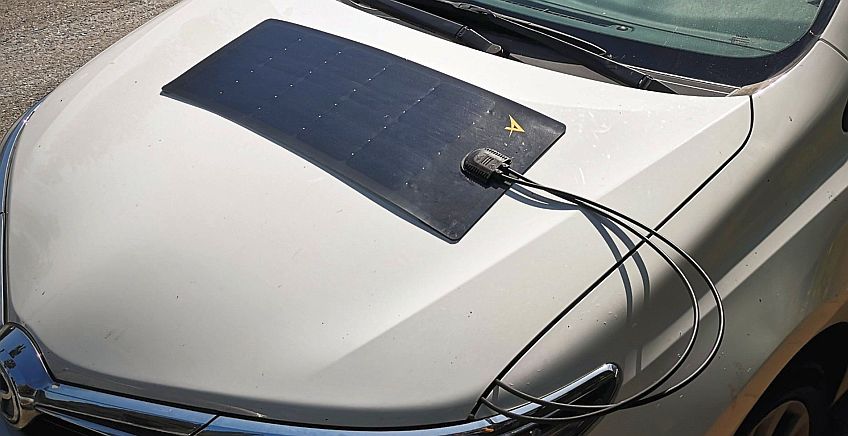

Using flexible films is primarily suitable for the electric and hybrid vehicles market since they are light and capable of being deployed all over the vehicle’s surface, such as the roof and the hood. In addition, this technique provides the car with an additional energy source which, in turn, allows for a greater range or, alternatively, reduces battery volume. Also, these films are more resistant to vibrations.

In the fleet market, Apollo designates its films to be deployed on trucks and buses’ roofs. The israeli retailer Osem, for instance, has already deployed films on around 90 delivery trucks. They are also suitable for fuel-operated buses and trucks, where electrical systems are used for loading and unloading. Rosenberg: “Currently, the busses and trucks market is the largest. Hundreds of buses around the globe are equipped with our films, which save the operators about 5% of their fuel consumption. They also contribute to noise reduction in an urban environment since the engine is not in use while unloading. The ROI in this area is fast, usually an average of a year”.

The film turns into an integral part of the car’s roof and hood

In the private car market, the company has the Volkswagen order and initial cooperations with Audi and Hyundai, which have not yet been commercialized. At the Audi pilot, the integration of the film in the roof and the hood is carried out in the vehicle’s manufacturing phase. The film is attached to the chassis by compressing, making them an inseparable, esthetic component of the vehicle’s surface. “For several years, Audi tried to turn the roof into a power producer, and they succeeded with us. This is because our solar films are flexible, stay stable during the production process, and their performance is steady despite the car’s vibrations”. According to Rosenberg, the Audi project is in its advanced development stages.

The company has reported that its product energy utilization reached 16.75% now, which is a relatively high rate compared to competitive solutions. The weight of each film is 1-4 oz for sqft. “In the flexible solar market, our films are the most efficient, flexible, and inexpensive, thanks to unique coating materials, advanced production methods, and intricated optics. In addition, we put much effort into catching up with the conventional panels, which currently provide a 21% utilization rate”.