Inertial Sensing Solutions for Autonomous Machines

28 February, 2018

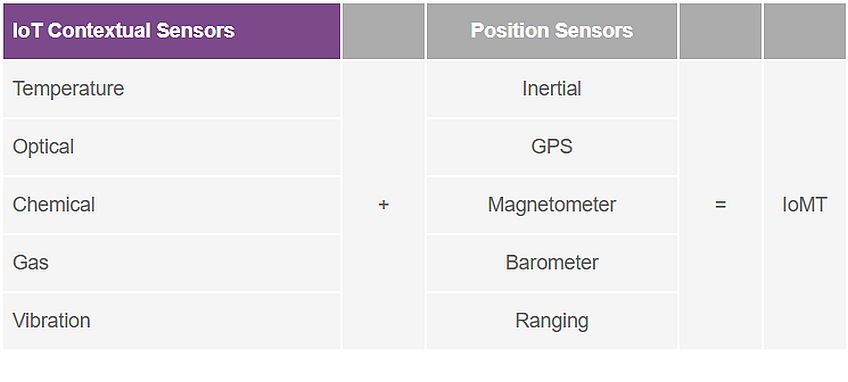

Intelligent and accessible sensor systems are revolutionizing the industry. This Internet of Moving Things fuses contextual and positional data, and essentially amplifies its usefulness

By Bob Scannell *

The automation of industrial machinery promises great gains in resource efficiency, equipment accuracy, and safety. A key enabler of these gains is the identification of the appropriate sensing technologies to enhance the contextual knowledge of the equipment’s condition. To the extent that the location or position of the equipment is also a valuable input to the equation, then precision inertial sensors hold the promise of essentially pinpointing location or maintaining accurate positioning. In many situations, the determination of position while operating in a complex or harsh environment is of especially critical value.

Contextual Sensing

Intelligent and accessible sensor systems are revolutionizing what would otherwise be mature industries, turning agriculture into smart agriculture, infrastructure into smart infrastructure, and cities into smart cities. In some cases, where mobility is important, geolocating this contextual sensor data is then required. In fact, little of the Internet of Things can be considered static. Equipment in factories, fields, and hospitals is more useful when mobile, and an optical sensor on a geographically static piece of equipment is still likely locally mobile, requiring steering and pointing.

This Internet of Moving Things fuses contextual and positional data, and essentially amplifies the usefulness of the data and the efficiency gains. As an example, for analyzing yield enhancement opportunities, imagine the difference in relevance of knowing the temperature, moisture, and precise location of an individually planted seed vs. simply knowing the temperature and soil condition of a field of randomly planted seeds.

Inertial Sensors Within Smart Machines

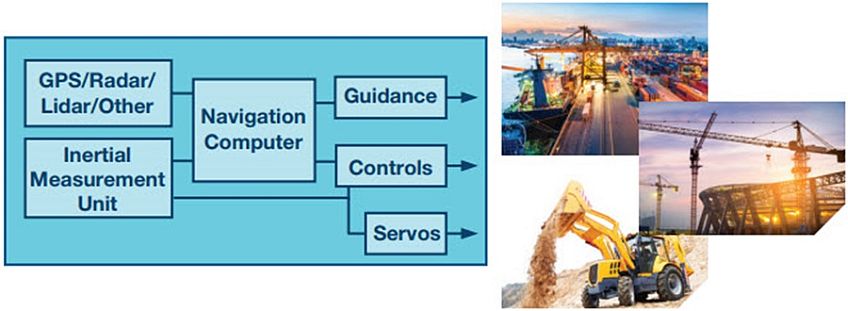

Inertial sensors serve two primary functions within most smart machines; that of either equipment stabilization and pointing, or navigation and guidance. While GPS may be considered the navigational aid of choice for most systems, in some cases there are significant concerns to relying on GPS, primarily due to potential blockages. Transitioning to inertial sensing during a GPS blockage is effective, but only assuming the inertials are of sufficient quality to provide adequate precision for the duration of the outage.

In the case of a stabilization or servo loop, inertial sensors may be relied on in the feedback mechanism, to maintain a reliable pointing angle of an antenna, crane platform, construction blade, farming implement, or camera on a UAV. In all of these examples, the purpose goes beyond providing a useful feature (for example, gesture control in a mobile phone), to delivering critical accuracy or safety mechanisms.

Sensor Quality Matters

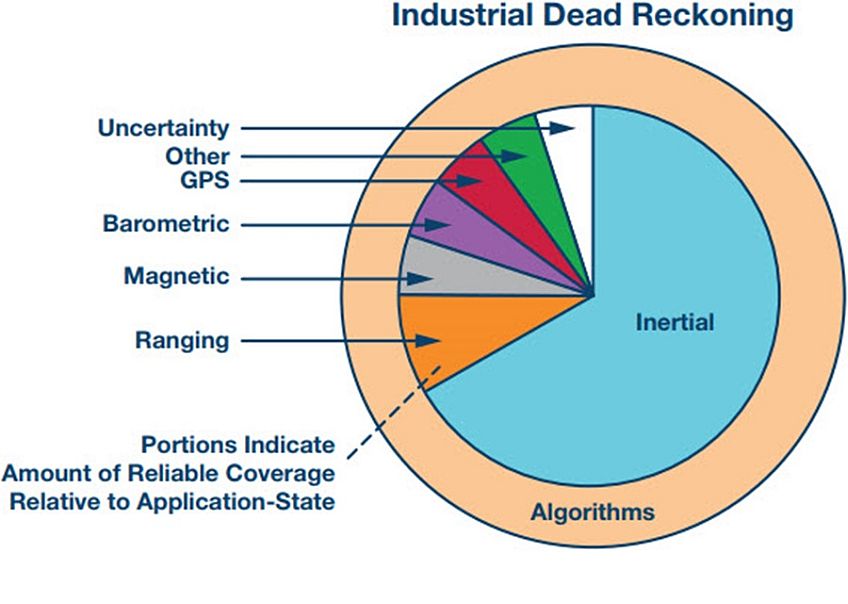

A conceptual example of the role of sensor fusion in an industrial application is illustrated in figure below. Here, for a precision driven industrial application, a careful selection of sensors has been done to support an expected need to operate within high potential GPS blockages, potentially difficult magnetic fields, and other environmental disturbances. For this reason, the infrastructure free nature of inertial sensors is most heavily relied on, with other sensing aids chosen to support specific environmental challenges, and to help correct for any long term inertial drift.

Ultimately, the end application will dictate the level of accuracy required, and the quality of sensor chosen will determine whether this is achievable. A low precision sensor may be suitable if it is only to be relied on in limited instances, and if the application has tolerance for error. In other words, if it is not safety or life critical. Though most consumer level sensors have low noise and perform adequately in benign conditions, they are not suitable for machinery subject to dynamic motion, including vibration, which in a low performance inertial measurement unit cannot be separated from the simple linear acceleration or inclination measurement .

To achieve accuracy of better than 1 degree while operating in an industrial environment, the selection focuses to sensors that are designed specifically to reject error drift from vibration or temperature influences. Such a high precision sensor is then capable of supporting a larger span of the expected application states, and over longer time periods.

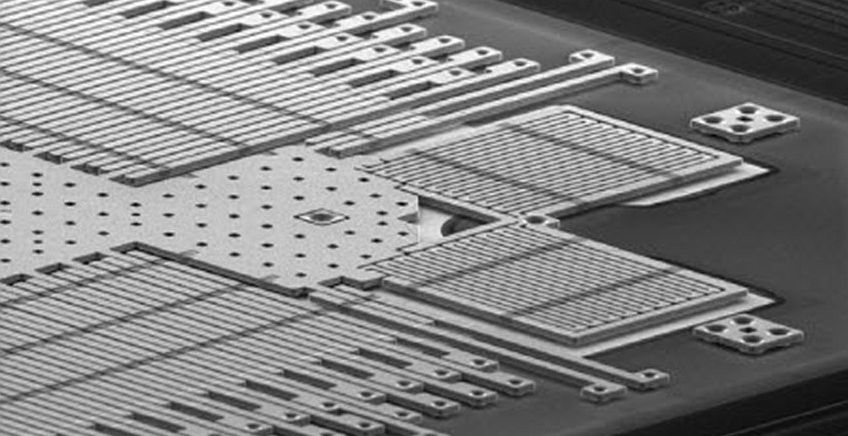

Designing a MEMS structure with a primary goal of cost reduction will typically sacrifice performance, sometimes significantly. Some simple choices for reducing cost, such as less silicon mass and plastic encapsulated consumer packaging, are largely detrimental to MEMS performance. Extracting accurate and stable information from a microelectromechanical device, requires strong signal-to-noise driven by silicon area and thickness, as well as minimized stress imposed to the silicon, from the selection of component packaging through to system-level enclosures.

System Trade-Offs

The majority of complex motion applications require a full IMU (Inertial Measurement Unit) with three axes of both linear acceleration and angular rate motion, to adequately determine positioning. IMU functionality is available today in both chip level (consumer) form, and in module level integration (industrial). Though logically it may seem that the consumer chip level IMU is more advanced in system integration, the opposite is true when the end goal is accurate motion determination in a complex industrial environment.

In the case of the industrial IMU, high performance is available out of the box. The same high performance is reliably attained over the life of the application, with minimal requirement, if any, for in system correction. Consumer IMU, though seemingly fully integrated and complete, requires significant time, integration, and cost to attempt to achieve similar levels of performance (typically not even possible), and likely still never achieves equally reliable operation.

* Bob Scannell is a business development manager for ADI’s MEMS inertial sensor products.